|

GIGA (Tianjin) import&export Co,.ltd

|

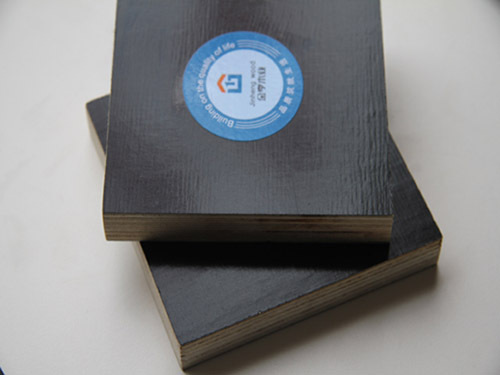

concrete film faced plywood

| Price: | 15.6~22.3 USD |

| Payment Terms: | T/T,L/C,D/A |

| Place of Origin: | Tianjin, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.MANUFACTURE SALES

2.100% full poplar core

3. melamine film faced plywood

4.2 time hot pressing

5.strong black film

Film faced phenolic poplarPlywood features a surface paper film impregnated with a phenolic resin and applied under heat and pressure. It was originally used primarily for fine faced concrete work and vehicle building. Phenolic plywood is also now used in access towers and scaffolding systems.

The plywood is edge sealed to minimise the ingress of water.

Film faced plywood is available with a smooth glass like finish on both faces or with a mesh pattern imprinted on the face to improve anti slip properties.

The surfaces are hard wearing, and different weights of film are available to suit the abrasion and wearing performance required.

The plywood is edge sealed to minimise the ingress of water.

Film faced plywood is available with a smooth glass like finish on both faces or with a mesh pattern imprinted on the face to improve anti slip properties.

The surfaces are hard wearing, and different weights of film are available to suit the abrasion and wearing performance required.

Film Faced Plywood

Sizes: 1220X2440mm

Thickness: 4mm-50mm (Other sizes and thickness values are also possible, as per customer's request.)

Length (width) tolerance: +1,0 mm -1,5 mm

Surface quality: film, smooth, wire mesh, hexagonal

Color of surface: Black, Brown and others on customers' request

Material of core: Poplar, birch, hardwood, bamboo, combi

Film weight: 120 - 220 g/sq.m

Glue: Phenolic Resin, Melamine Glue, and Mix Glue.

Edges processing: Waterproof acrylic paint

Sizes: 1220X2440mm

Thickness: 4mm-50mm (Other sizes and thickness values are also possible, as per customer's request.)

Length (width) tolerance: +1,0 mm -1,5 mm

Surface quality: film, smooth, wire mesh, hexagonal

Color of surface: Black, Brown and others on customers' request

Material of core: Poplar, birch, hardwood, bamboo, combi

Film weight: 120 - 220 g/sq.m

Glue: Phenolic Resin, Melamine Glue, and Mix Glue.

Edges processing: Waterproof acrylic paint

Packing and Loading Details

Goods are packed in standard export packing.

Inner packing: Inside pallet is wrapped with a 0.20mm plastic bag.

Outer packing: Pallets are covered with plywood/ AB carton and then PVC/steeltapes for strength.

Transport: By break bulk or container (Qty: 8pallets/20'GP, 16pallets/40'GP,18pallets /40'HQ).

For detailed Loading Details, please download

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Film Faced Plywood

Black Film Faced Plywood

Brown Film Faced Plywood

Formwork Film Faced Plywood

Antislip Film Faced Plywood

Plywood Film Faced

More>>