|

GIGA (Tianjin) import&export Co,.ltd

|

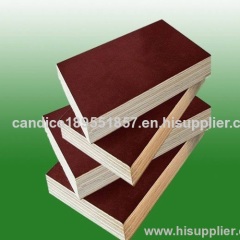

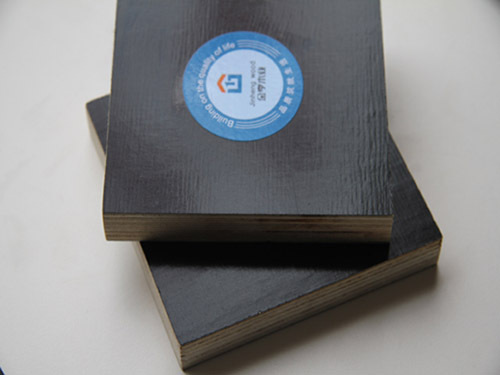

1220*2440*18mm high quality film faced plywood sheets

| Price: | 15.6~22.3 USD |

| Payment Terms: | T/T,L/C,D/A |

| Place of Origin: | Tianjin, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.MANUFACTURE SALES

2.100% full poplar core

3. melamine film faced plywood

4.2 time hot pressing

5.strong black film

1220*2440*18mm high quality film faced plywood sheets

Detailsof our quality guarantee:(why choose us )

1. putting the film faced plywood in boiling water for 48 hours, it is still glue-sticking and non-deformed

2.physicall specification is better than iron moulds and can satisfy for the request of the construction:drialling,sawing,nailing,etc.

3. (can sign the quality agreement, fails to reach re-use times, fees at our company account)

WBP plywood re-use for above 20 times

Melamine plywood re-use for above 15 times

4.our main advantages are :100% whole piece of poplar cores, pure glues of melamine/wbp/mrmade by ourselves without any impurity and two times hot pressing.

Panels should be stored in a dry place over leveled crossbars.

Panels should be carefully handled so that the faces and edges are not damaged.

Cutting and drilling of the panels to be done with appropriate tools to av oid damaging of the panel surfaces.

oid damaging of the panel surfaces.

oid damaging of the panel surfaces.

oid damaging of the panel surfaces.After cutting and/or drilling, the fresh surfaces should be sealed with water-resistant paint.

Prior to using the panels, shuttering oil should be used for easier panel removal.

It is recommended upon building the shuttering structure, only specially designed mounting elements to be used.

Panels should be stored in a dry place over leveled crossbars.

Panels should be carefully handled so that the faces and edges are not damaged.

Cutting and drilling of the panels to be done with appropriate tools to avoid damaging of the panel surfaces.

After cutting and/or drilling, the fresh surfaces should be sealed with water-resistant paint.

Prior to using the panels, shuttering oil should be used for easier panel removal.

It is recommended upon building the shuttering structure

Important!

Film faced plywood is designed to be used15-30 times.

The effective multiple and cost-saving use is utterly dependent on the proper panel handling and care!

Related Search

Film Faced Plywood

Black Film Faced Plywood

Brown Film Faced Plywood

Formwork Film Faced Plywood

Antislip Film Faced Plywood

Plywood Film Faced

More>>